RecyclingAKTIV & TiefbauLIVE: Large range of attachments for all kinds of carrier systems

As companies face rising material and labour costs, the use of innovative technology to boost efficiency on construction sites is an important competitive advantage. Visitors to RecyclingAKTIV & TiefbauLIVE from 27 to 29 April 2023 in Karlsruhe will be able to experience attachments, interfaces and digital assistance systems live and up close. From compressing, excavating and milling to crushing, screening, grabbing and mixing, dozens of exhibitors will showcase their technological solutions in a broad range of applications, either at their own stands or in the specially designed attachments arena. The perfect coordination of the carrier system, attachment, and rotation and changeover system holds great potential for improving construction site processes, making more efficient use of staff and reducing costs.

Tiltrotators enabling versatile use of construction machinery

The cylinderless NOX tiltrotator from KINSHOFER is designed for excavators with an operating weight of 3 to 25 tonnes. Thanks to a 360° continuous rotation and a swivel angle of 2 x 50°, the tiltrotator transforms excavators into multi-functional attachment carriers. The quick-change coupler and selection of attachments enable excellent efficiency on any construction site. As a result, operators can perform more and different types of work processes even faster, whilst also increasing safety across the working environment. KINSHOFER will demonstrate the tiltrotator live with various attachments, such as multi-purpose grippers or levelling buckets.

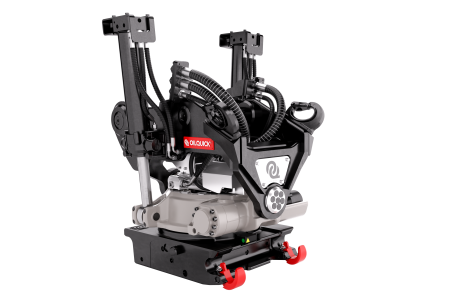

OilQuick will showcase its new Zero Degree technology. The market leader for fully hydraulic quick-change systems will use this year’s trade fair to focus on one product area in particular: the tiltrotator. The Zero Degree technology means that the rotational plane of the new tiltrotators runs parallel rather than at an incline. This allows any attachment to be used without having to correct the tumbling motion of conventional systems. Training time is reduced as a result, while the technology also prevents dangerous situations arising on the construction site.

Excavator scoops for every application

The liquid soil bucket from Tibatek enables cost-effective production of liquid soils on site. It processes the excavated earth by adding compound and a set volume of water, producing a fluid, self-compacting backfill material in just 5-6 minutes. The system best displays its advantages over conventional products in areas where tight spaces make installation and compacting more difficult. As well as producing liquid soils, the mobile mixing bucket can be used to produce small quantities of concrete without the need for a mobile concrete mixer.

Rädlinger will present its new X-TREME backhoe. This is based on the standard backhoe that was given a number of specific modifications to respond to customer wishes. These include reinforcing corners on the interface, a larger tooth system, a stronger blade, more robust side walls and base made from HB400, stronger side cutting edges and a thicker wall on the bucket box. The wear-resistant design significantly extends the service life compared to normal backhoes, therefore making the carrier more economical. The X-TREME is available for excavators with an operating weight of 11 to 50 tonnes.

Bucket screeners enable recycling of waste material

In the outdoor exhibition area, Predatore will demonstrate various bucket screeners in its PP, PS and PX series. Tailored to customer requirements, the separators are available in grading curves of 10 to 80 millimetres in 5 millimetre steps. With its cutting-edge separator technology, the PP series in particular offers enormous volume and high throughput, while also helping to protect the environment. This is because the robust bucket screeners can recycle a plethora of organic and mineral waste into usable materials.

The Terra-Star® bucket screener from Kronenberger oecotec is designed as an attachment for hydraulic excavators and wheeled loaders. The horizontal shafts are fitted in enclosed, zero-maintenance bearing units and flanged in front. With the QUICK quick-change coupling, users can replace the shafts without having to remove the bearing or chains. This allows for versatile use with the same unit. It also significantly reduces downtimes resulting from having to replace the shafts due to wear. The Terra-Star® is available with various shaft designs. These can also be ordered on an after-sale basis as shaft kits.

You can find the shown press pictures for download on the german page